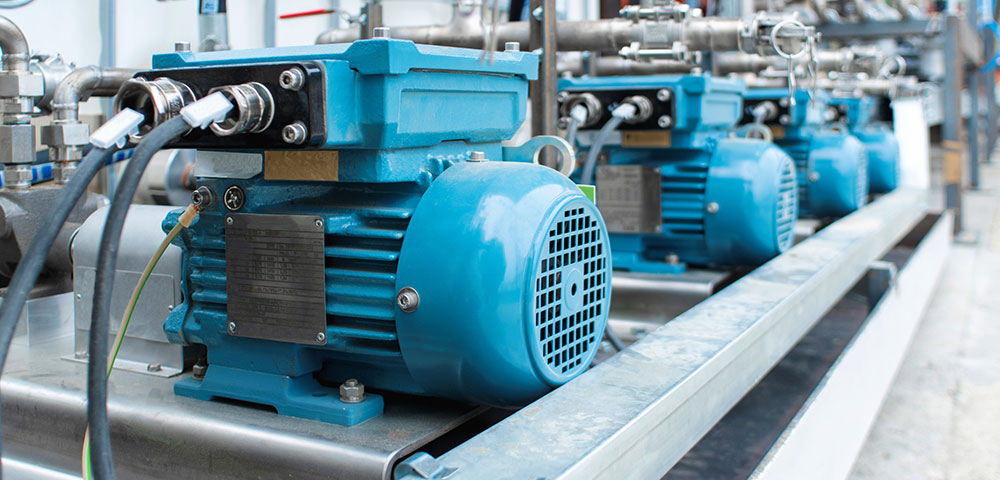

Product group strategy engines

Goal: Supplier management & cost reduction of the product group engines by 10%

Project

Duration: 1.5 years

Role in the project: Project Manager

Operational area, geographical:

- Austria

- Global

Company

Type: Mechanical / plant engineering

Turnover: 700 Mio. EUR

Number of employees: 4,200

Description

Purchasing volume EUR 2.8 million

- 7 Suppliers (1 main supplier)

- Introduction of new energy efficiency standards was imminent

Measures

- Buy-in of the development / logistics and production departments at the 2 main locations in Austria

- Definition of the team members of the different departments / plants

- Project plan preparation and adherence

- Preparation of the specifications for the suppliers

- Solicitation and comparison of offers on a main group basis

- Technical and commercial comparison of the offers

- Application test in the development department

- Supplier negotiation of the 3 best offers

- Framework contract negotiation with the 2 best suppliers

- Contract signing

- Presentation of the results to the management

- Conversion (run-in phase/run-out phase)

- Accompaniment of the supplier introduction

Team

- 1 Subproject manager technology

- 6 Development engineers at 2 locations

- 2 Logistics employees at 2 locations

- 1 Strategic buyer

Reporting

- Weekly team meeting: comparison of target and actual status

- Monthly reporting Head of department

- Presentation of the results to the management

Interfaces

- Purchasing

- Technology (development)

- Disposition

- Manufacturing / Production

- Accounting & Controlling

- Suppliers

Success

- Expansion of the company’s market leadership through future-proof technology and partners

- Appreciation of purchasing as a “partner at eye level” by development, suppliers and management

- Material cost savings of 330 KEUR (12%) including technology improvement

Share